Changing inter-occupational competencies in the wake of the digital shift

Perspectives for the regulatory and implementation levels

Gert Zinke

Between 2016 and 2018, a project team at BIBB conducted occupation screenings as a part of the BMBF/BIBB initiative “VET 4.0 – Qualifications and competencies of skilled workers for the digitalised work of tomorrow”.* The impacts of digitalisation were investigated for 14 recognised training occupations. The present article describes the approach adopted in the project and pools findings from the various sub-studies. The focus is directed towards competencies that are evaluated as being particularly important in cross cutting terms. The article concludes by outlining a proposal for how such competencies can be fostered within the framework of an altered didactic design to which training regulations are already according consideration.

Changing occupational profiles as a result of the technological shift

Occupations undergo constant development. Work tasks alter as general conditions, tools, and process sequences change. In her novel “Mittagsstunde” (“Midday Hour”), for example, Dörte Hansen characterises the agricultural machinery mechanic of the 1960s as follows. “When the grass and hay season arrived, Haye Nissen no longer concerned himself with horseshoes and scythe blades. He ceased being a blacksmith and became a mechanic instead. He lay beneath foragers and hay balers, repaired drive shafts … and hurried into the fields in dirty overalls and carrying a tool box whenever tractors stopped working or combine harvesters refused to move.” (p. 218). The current occupational title of “agricultural and construction machinery mechatronics technician” very much reflects this further development. Today, work tasks in this occupation include IT-aided diagnostic tools, preventative maintenance and multi-networked data management between machines and devices, and a linked process management system. The function of this system with regard to the relationship between the manufacturers and the operators of machines is becoming ever more important. The questions which immediately arise are what the characteristic nature of the occupation will be in ten years’ time and how initial and continuing vocational education and training can prepare skilled workers for changed requirements.

Early recognition of such a shift in demand is a permanent matter of concern for skills research and educational policy in equal measure.2 When preparations for the BMBF/BIBB initiative began, recourse was available to investigative approaches and results that had already been applied (cf. Becker/Spöttl 2008, Spöttl 2016, Pfeiffer 2016, Windelband 2006).

Aim of the occupation screening and selection of occupations

The overarching objective of the occupation screening was to use several sample occupations to achieve the early recognition, evaluation, and comparison of changes to requirements caused by digitalisation. The intention was to use this as a basis for the submitting recommendations for the design of initial and continuing VET in the occupations forming the object of investigation and for the further development of the VET system in overall terms and for these recommendations to inform the VET policy debate.

The impacts of digitalisation on task structures in the workplace, on qualifications requirements for skilled workers, on the demand for skilled workers, and VET were studied via the example of 14 recognised training occupations in various branches and economic sectors (cf. Figure 1). The occupations were chosen so as to

- include as many economic sectors and industries as possible (technical, commercial, industrial, craft trade, agricultural and service sector occupations, and the liberal professions);

- cover an appropriate number of trainees, ranging from approximately 300 newly concluded training contracts per year to over 10,000;

- feature differing durations of training (two-year, three-year, and three and a half-year occupations);

- ensure that, as a rule, the most recent update of regulations had taken place at least five years previously and that no revision was immediately impending.

As Figure 1 illustrates, the occupations also vary in terms of the degree of digitalisation perceived at the company and occupational levels. Within the scope of the occupation screening process, skilled workers, line managers, and trainers were asked how they assess their company’s current level of digitalisation within the work area of the respective target occupation.

Figure 1: Evaluation of the degree of digitalisation within the work environment by training occupations (in per cent)

Research design and methodological approach

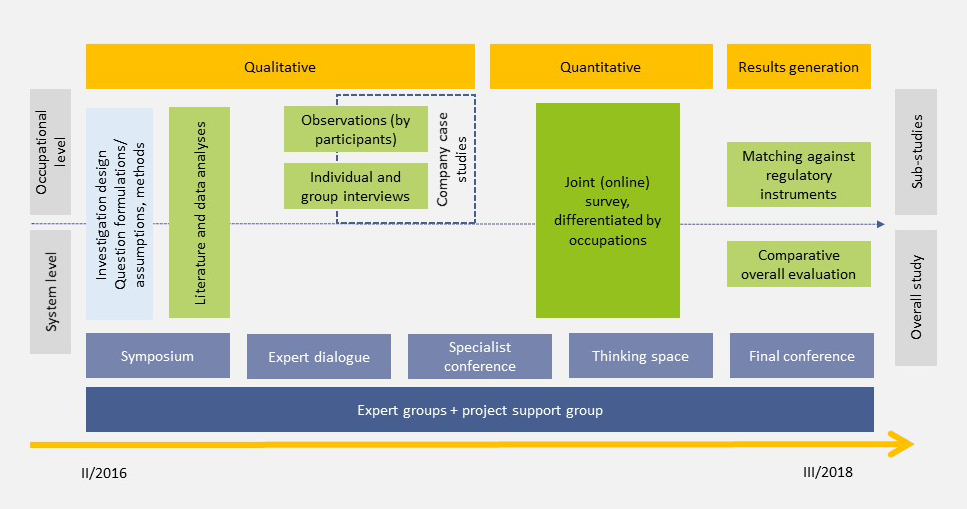

The methodological approach adopted within the scope of the occupation screening took place at two levels (cf. Figure 2). At the first level (occupational level), screening of the individual occupations was conducted, and results were collated in occupationally related sub-studies. The second level (system level) involved coordination and systematic comparative evaluation of the individual sub-studies (overall study). The research design, selection of occupations, formulation of questions, assumptions, and methods were determined by the project heads in accordance with a project planning and project design action framework. More detailed specifications were made by the project team during the course of the project. These included aspects such as preparation of the online questionnaire and terminological definitions, e.g. with regard to the degree of digitalisation. External experts were included in this process. The latter comprised expert groups of between three and five members, an overall project support group, and specialists who were involved in certain areas.

Figure 2: Research design and methodological approach

Literature, document and data analyses to determine the current status of research and state of affairs within the context of occupations and VET and digitalisation/Industry 4.0 were conducted at both levels. Between four and 15 company-based case studies, preferably at pacemaker firms, were carried out per occupation on the basis of these partial results. The core focus was on guided interviews with skilled workers, line managers, and training managers. This was supplemented by observations from participants and/or by company inspections. Pacemakers are companies which have been identified as pioneers in the use of digital technologies within the respective training occupation environment. When selecting the companies, care was also taken wherever possible to choose firms which were typical of the training occupation in terms of aspects such as size, sector, and business model.

The partial results generated were relayed to the expert groups and made available for debate within the framework of various events formats. In order to secure an even broader basis of validity for the results, the qualitative phase was followed by a quantitative stage which began around the middle of the project term. An online survey was prepared, realised and evaluated with the assistance of an external provider, and a total of more than 2,000 returns were recorded. Most of the questions were closed and were largely identical for all occupations. In some cases, additional questions were included and/or items were adapted in an occupationally related way with regard to technologies, works tasks, and skills and qualification requirements. In each case, a final matching against regulatory instruments took place. The intention here was to investigate the extent to which current training regulations already cover the qualification requirements identified in the investigation.

The results will be published together with the recommendations in eleven sub-studies3 (in some cases, two occupations were collated). The individual results will once again be compared and evaluated in the overall study, and further conclusions and recommendations will be formulated where possible. This also forms the basis for the following remarks.

Changes in competence requirements are discernible across all occupations

If we summarise the findings that emerge from the sub-studies, it is revealed that the digital shift is changing the skills, knowledge and competencies required in all training occupations investigated and that all competence areas are affected (professional competence, social competence and self-competence). The online survey enquired into the present and future significance of individual competencies.4 According to the respondents' assessments, which was possibly coloured by the way in which the questions were posed, all competencies seem to be gaining in significance (cf. Figure 3). At the same time, recognisable gradations are noticeable.

The following can be viewed as the most important competencies required.

- Occupation-specific knowledge and skills

- (Ability to) learn

- Process and system understanding

- Flexibility/spontaneity

- Digital competencies.

Figure 3: Evaluations of the development of the importance of selected skills, knowledge and competencies

Evaluations from the perspective of individual occupations

The key question posed in the individual and group interviews to identify changed competence requirements was: “What do you believe makes a good [occupational title]? Which competencies does he or she need to possess in order to meet current and future challenges?” Catalogues of key words served as a support template, and competency cards were also used in some interviews. Responses regarding the competency “Process and system understanding” are presented below as examples for selected occupations.

Agricultural and construction machinery mechatronics technician: “Mechanical systems are steered by hydraulics and electronics, and you need to know the correlations of the processes. You need to think in processes. Mechanics, hydraulics, and electronics cannot be viewed individually. There is a huge interplay between the three main pillars. You have to be able to see this. It is also very important to carry out trouble shooting in a systematic way” (Head of Training at an inter-company vocational training centre).

Orthopaedic technician: “… but what we really need to train is a sense for processes and interfaces. And this is something completely different. I do not see it as an advantage that, generally speaking, everything can now be simply and quickly digitalised with the young generation. This is not necessarily a benefit, because they have no experience at all with processes and interfaces. It really is the case that even our very young trainees have no idea about this.” (Master orthopaedic technician and truss maker, managing director).

Mechanic in plastics and rubber processing: “Ultimately, they must once again see the process as a whole, and in terms of their activities […], they have to gain a picture of where what they do really has an impact.” (Manager).

Industrial clerk: “When I think about the skilled workers of tomorrow, […] the situation is that processes will constantly need to be adapted and enhanced. My view is that this is only possible if I have a transparent picture of a process and can understand it” (Head of commercial training, major company).

These assessments allow areas of potential for the fostering of process and system competency to emerge at several levels. The most obvious of these, however, seem to be updating training occupations and the closer integration of relevant skills, competencies and knowledge. This is recommended for eight of the occupations investigated in connection with other reasons for updating. Several sub-studies also see an opportunity for the introduction of additional qualifications, within the scope of either new or amended regulations. If we turn our attention from the regulatory to the implementation level, starting points for the promotion of process and system competence are also revealed from a methodological and didactic perspective. These are outlined below.

Conceptual shift in the imparting of training contents

One possible solution from a methodological and didactic point of view is that the way in which training is structured – from the development of regulatory instruments right up until the design of time-constrained phases of teaching and learning – could abandon the inductive direction favoured up until now and replace this will a deductively aligned approach. This means that there will be more emphasis on using the system or the process as a basis to move towards and infer individual work tasks rather than vice versa, i.e. progressing from the tasks to the system or process. This approach has already been presented in a previous study and has, for example, been gradually introduced by an automobile manufacturer (cf. Katzer/Kreher/Zinke 2017).

Indeed, initial steps in this direction are possible on the foundations of existing training regulations. Overall systems typical of companies and occupations, the functionality of which could, if necessary, initially be presented in a simplified way and be supported by models or simulations, may act as terms of reference for the deductive approach. In the case of the automobile manufacturer, a model of an automated assembly system, which the company referred to as a works model, was selected for this purpose. This means, for example, that learning assignments or project work relating to the explanation of functionality, the documentation of a process sequence, troubleshooting or the expansion or alteration of a plant can be used as vehicles from the very outset of training. These can be used to impart action patterns that are aligned to a process and system-based philosophy. The assumption is that trainees will perceive such an approach as more respectful and more motivating that previous inductive methods that are oriented towards “basic principles”. Learning assignments and project work can be developed to this end and may also serve as a topic for future pilot projects.

In the case of a modernisation of training regulations, if such an approach were to be robustly pursued, the scheduling and organisational structure of the general training plans would need to be rearranged in such a way so as to stipulate time windows at the start of training for the kinds of knowledge, skills and competencies to be imparted.

-

1

VET 4.0 – Qualifications and competencies of skilled workers for the digitalised work of tomorrow (term April 2016–October 2018), cf. www.bibb.de/de/dapro.php?proj=7.8.154 (retrieved: 08.04.2019)

-

2

Cf. e.g. in this regard www.frequenz.net.

-

3

The sub-studies will be published over the course of 2019 in the BIBB series “Academic Research Discussion Papers” (cf. www.bibb.de/veroeffentlichungen/de/publication/series/list/8, retrieved: 08.04.2019).

-

4

The relevant items for the project were determined on the basis of various sources (results of the case studies, knowledge, skills and competencies included in the regulatory instruments, third party questionnaires).

Literature

Becker, M.; Spöttl, G.: Berufswissenschaftliche Forschung. Frankfurt/M. 2008

Hansen, D.: Mittagsstunde. Berlin 2018

Katzer, O.; Kreher, S.; Zinke, G.: Ausbildungsgestaltung in der digitalisierten Arbeitswelt Beispiel: Produktionsunterstützende Fachkräfte in der Automobilindustrie. In: BWP 46 (2017) 2, pp. 24-27 – URL: www.bibb.de/veroeffentlichungen/de/bwp/show/8292 (retrieved: 08.04.2019)

Pfeiffer, S. u.a.: Industrie 4.0 – Qualifizierung 2025. Frankfurt/M. 2016 – URL: www.vdma.org/documents/105628/13417295/VDMA%20Studie%20Industrie%204.0%20-%20Qualifizierung%202025.pdf/bbfe37d6-f738-4558-b2b7-1b01a04d166c (retrieved: 08.04.2019)

Spöttl, G. u.a.: Industrie 4.0 – Auswirkungen auf Aus- und Weiterbildung in der M+E Industrie. München 2016 – URL: www.baymevbm.de/Redaktion/Frei-zugaengliche-Medien/Abteilungen-GS/Bildung/2016/Downloads/baymevbm_Studie_Industrie-4-0.pdf (retrieved: 08.04.2019)

Windelband, L.: Früherkennung des Qualifikationsbedarfs in der Berufsbildung. Bielefeld 2006

Translation from the German original (BWP 3/2019): Martin Kelsey, GlobalSprachTeam, Berlin